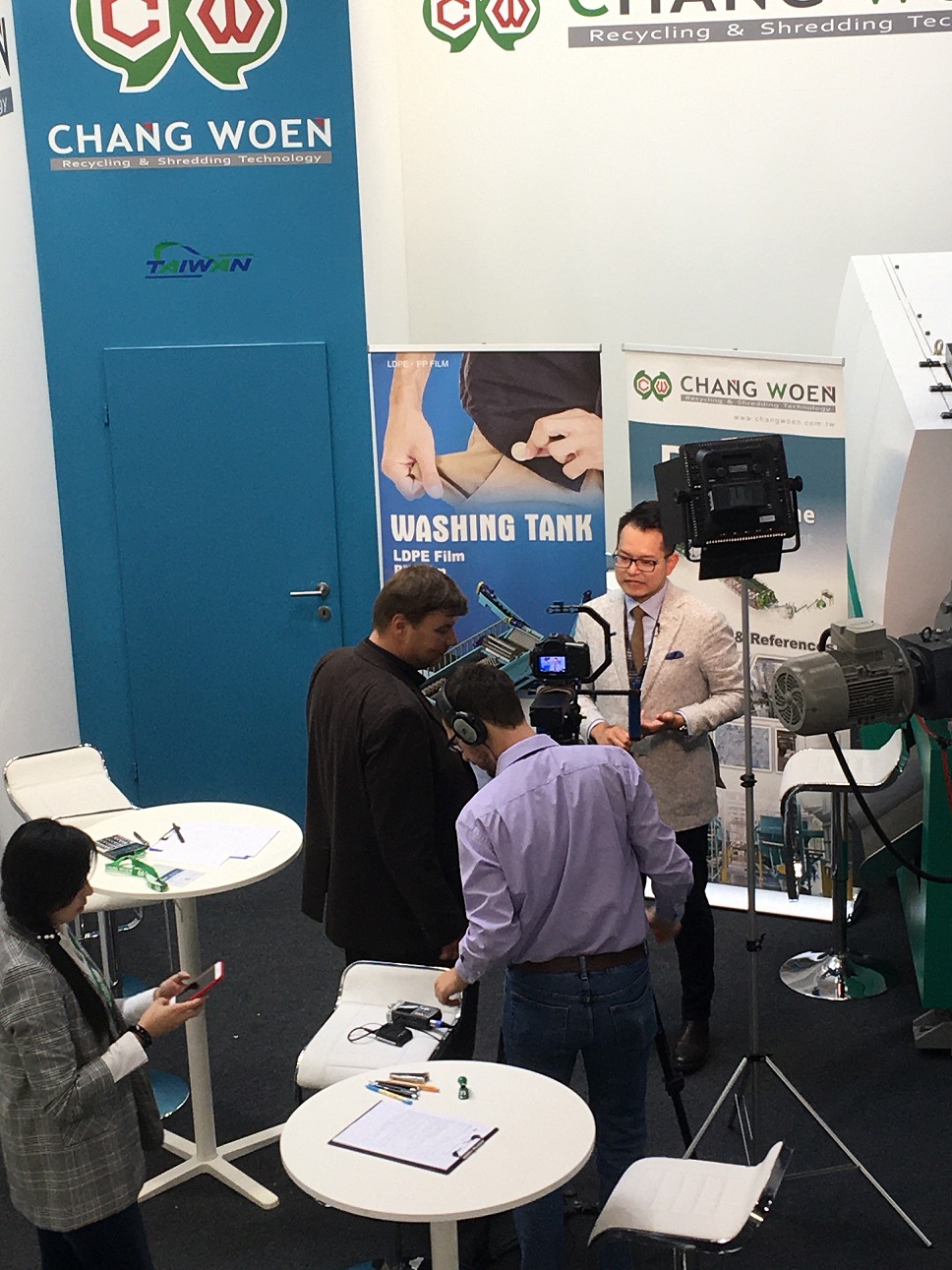

ABOUT CHANG WOEN

Crusher | Size you decide, Capacity we deliver

Chang Woen is a specializing in manufacturing recycling machine with the experience of more than 25 years. Recycling machine plant including shredder machine, crusher machine

CSR

let’s us save our Earth Save Environment

Natural environment is everything for healthy life; we should maintain it.

It’s time to change our thinking into action! Just save the environment.